The Covid-19 pandemic in the last 18 months has affected everyone in different ways, and we all have to find ways to adapt to how we work and live our lives. When the pandemic started to spread around the world in February 2020, it was right in the middle of the Academy of Chocolate competition. Usually the judging is held in-person at a catering college in London from February to May, and we managed to finish judging the bonbons in February without any disruption. However, the bean-to-bar chocolate judging was supposed to start around late March 2020, and with the UK going into lockdown for a few months at that time, the judging didn’t restart until October 2020 and it was all remote judging. Only the more experienced judges were invited to this remote judging.

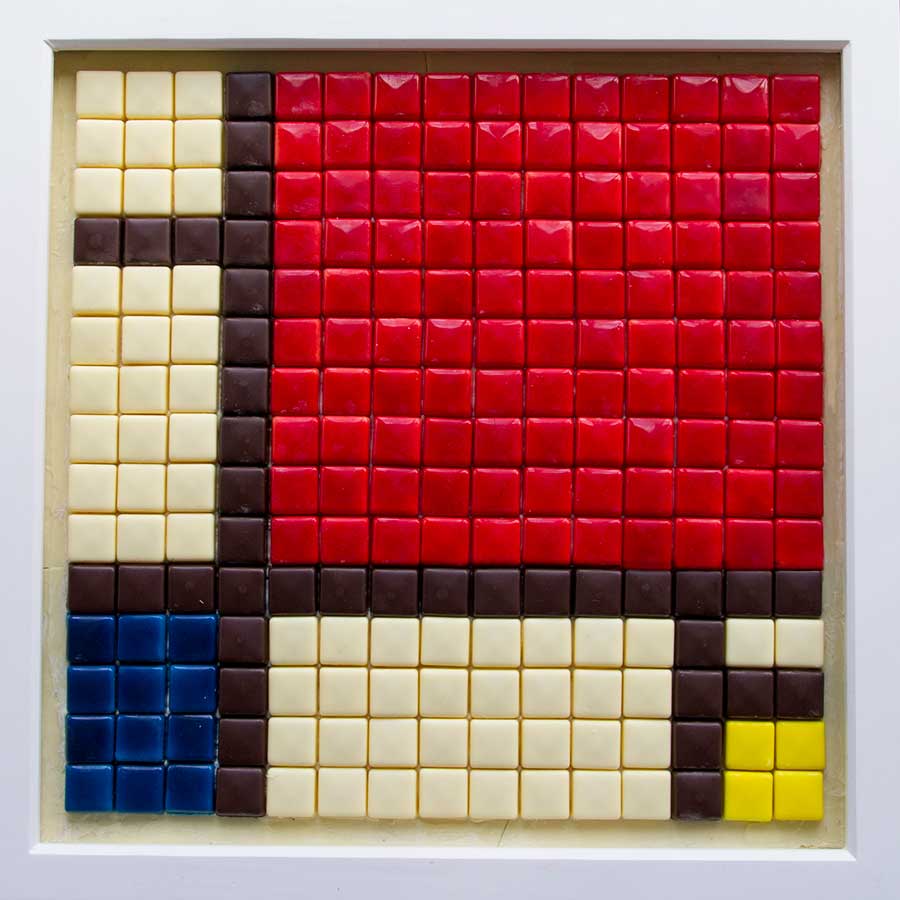

One of the last in-person judging at Academy of Chocolate in February 2020 before the Covid restrictions came into force

With the virus continuing to wreck havoc around the world, this year the bonbons competition has been postponed until the autumn, but the judging for the bean-to-bar competition is currently ongoing. As the pandemic is far from over, the judging is once again done remotely by the more experienced judges, and having learnt from last year’s judging, this is how the judging is conducted currently:

- The judges are divided into groups of 3. Each group would be sent approximately 50 bars in each round – round 1 was completed in June and currently we are in the middle of round 2. Each group would have a lead judge who will coordinate how the judging will be performed in the group and obtain consensus on the group score/award for each product. With the social distancing and travel restrictions, most people have made use of Zoom or Google Meet. Some groups do the judging “together” in several calls, while others have chosen to judge individually first and then meet virtually to discuss any discrepancies/disagreements on the scores.

- Each judge would be sent a whole bar for each product – this is for health & safety reasons, to reduce contact with the judging products by the Academy of Chocolate coordinating staff to a minimum. Usually with in-person judging, the staff would break the bars into pieces onto plates on the day, and the judges would be blinded to the products. However, with remote judging, this is tricky, as opening and breaking the bars, and packing the pieces into individual bags, may mean that by the time the bars arrive at the judges, the products have already been out of their original packaging for a while.

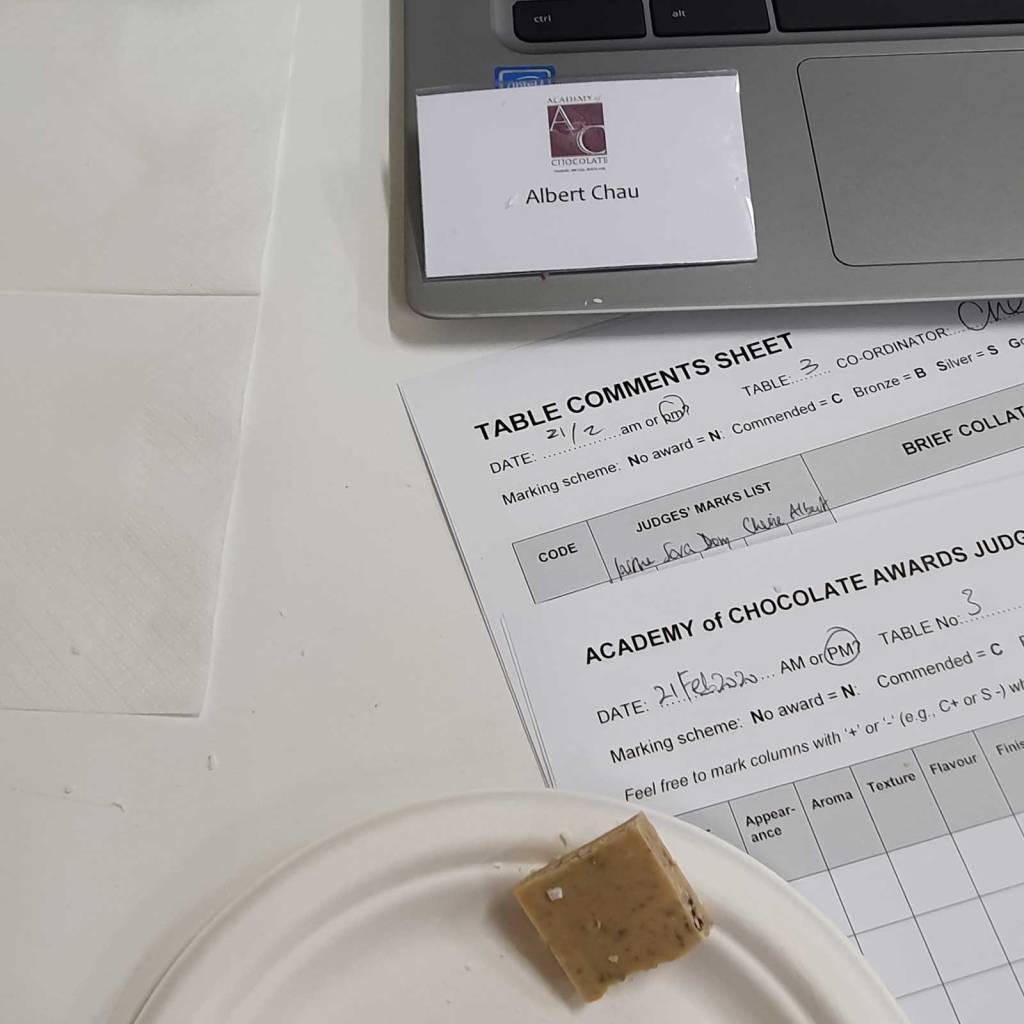

Remote judging via Google Meet with fellow judge Cherrie Lo in November 2020

There are pros and cons of remote judging compared to in-person judging. Here are some of the disadvantages:

- You don’t meet fellow judges in person and sit around tables to judge each product under the same condition, as well as mentoring the more junior/less experienced judges (usually each judging table would have a mixture of judging experience).

- Knowledge exchange plays a key part of the judging – with inclusion bars, sometimes there may be an ingredient which is not familiar to most judges, and with in-person judging, often there’s at least one judge in the room who will know about the ingredient and it is useful to have some guidance on what to look for. However, with remote judging, this is more difficult, though a bit of internet search can often help.

- Judges are not blinded to the products. However, the judges are experienced enough not to be influenced by the knowledge of the makers/producers. I usually break up about 9-12 bars and judge them in batches – this provides some partial blinding as I can rarely remember the products by the time I have broken this number of bars in one go, before proceeding to judging the products.

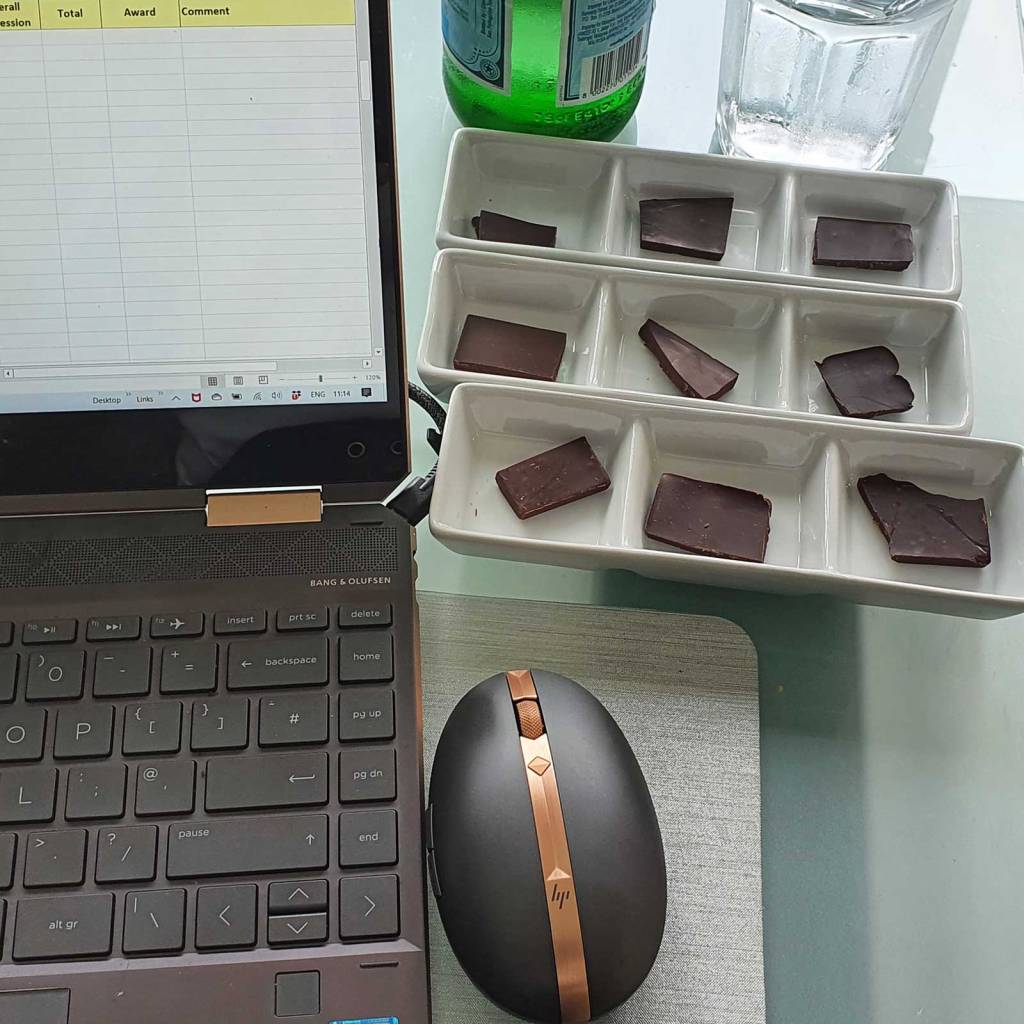

A technique to improve blinding to the chocolates during remote judging

- Occasionally you will find that the product is damaged and you only find out when you open the wrapper. This has happened to a few bars that were bloomed and damaged by heat – probably when they were sent from the other side of the world to London, and with the pandemic, sometimes even the air freight has become rather unreliable and may take several weeks to arrive. Usually when the bars are badly damaged, we would inform Academy of Chocolate staff who will then contact the entrants to have the products resent. With in-person judging, we didn’t see this problem often as the products would not have reached the judging tables, but also the shipping would have been more reliable.

However, there are several advantages with the remote judging that I quite like:

- With my group, we usually judge separately and we would then just get together once we have judged a substantial number of bars. This means that we are not influenced by the others in the initial judging. With in-person judging, sometimes the quicker judges may start commenting about the product whilst you are still trying to make up your own mind about the product. In my experience, most of the times the judges in my group all have very similar scores when we judge separately – there are a handful of “controversial” products which will require some discussions and retasting during the video calls.

An average amount of chocolate samples judged in one session before giving the palate a break

- I can decide when I judge the products and how many products I judge in one go with remote judging. With in-person judging, we are usually judging approximately 25-30 products in a 2-hour/3-hour session – Sometimes I do suffer from palate fatigue by the time I get beyond 20 products (especially if the session consists entirely of plain chocolate bars). With remote judging, I can take a break or stop whenever I feel the need to, and judge at a later time when my palate has recovered. If there are products which I am not totally sure about the scores (e.g. when I feel that my palate is not quite as sensitive on the day), I can always come back to them on another day. Also for any products that are worthy of an award in the initial tasting, I would usually repeat the tasting after I finish judging everything, to be sure that I am judging all the products consistently.

- With remote judging, some of the experienced judges who live far away from London can be more involved with the judging. Before, sometimes they would travel into London for the day, which is a big commitment, and also not ideal when the train is delayed and they would have to rush to the venue.

Will this kind of roundtable in-person judging return soon?

Is remote judging here to stay? This remains to be seen. For the AoC bonbons competition, the current plan is to have in-person judging in London later on this year, as repacking the bonbons and distributing them to the judges poses some additional challenges. Personally I can see the advantages of moving to a mixture of in-person and remote judging, and with the pandemic coming in waves with the new variants, this might not be a bad idea to remain flexible in order to keep the disruptions to competitions to a minimum, and to celebrate the work of the chocolate makers and chocolatiers from around the world.